SmarTherm Indirect

Features & Benefits

The Joule Smartherm range of commercial cylinders are KIWA certified and fully compliant for G3 installations. The cylinder is floor standing and manufactured from Duplex LDX 2102 3mm stainless steel sheet thickness and AISI 316L with 4mm thickness.

Categories: SmarTherm

General

| Item Code; | |||||

| 6bar. | TCFMVIX0300LFC | TCFMVIX0400LFC | TCFMVIX0500LFC | TCFMVIX0800LFC | TCFMVIX1000LFC |

| Indirect | 300 | 400 | 500 | 800 | 1000 |

| Titanium Imm. – Fact. Fitted As Std. | 2 x 3kW | 2 x 3kW | 2 x 3kW | 2 x 3kW | 2 x 3kW |

| Coil Surface Area (m2) | 1.54 | 1.97 | 1.97 | 2.86 | 2.86 |

| Coil Diameter (mm) | 32 | 32 | 32 | 38 | 38 |

| Coil Rating @60L/min 80ºC (kW) | 49 | 57 | 57 | 73 | 73 |

| Coil – Maximum Pressure (bar) | 6 | 6 | 6 | 6 | 6 |

| Inspection Flange | Optional – for inspection only – CANNOT be used with flanged immersion heaters | ||||

| All Cylinders – 3 & 6 bar | 300 | 400 | 500 | 800 | 1000 |

| Diameter (mm) | 620 | 710 | 710 | 920 | 1100 |

| Height (mm) | 1670 | 1670 | 2030 | 2050 | 2170 |

| Hot And Cold Connections BSP F | 1.5” | 1.5” | 1.5” | 2.0” | 2.0” |

| Coil Conn. (+for the solar coil) BSP F | 1.5” | 1.5” | 1.5” | 1.5” | 1.5” |

| Secondary Return BSP F | 1.25” | 1.25” | 1.25” | 1.25” | 1.25” |

| Max. Op. Pressure – 3/6 bar kit (bar) | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 |

| T&P Setting 3/6 bar kit (bar) | 7 / 10 | 7 / 10 | 7 / 10 | 7 / 10 | 7 / 10 |

| T&P Size – Multi Energy / Indirect+Solar | 1.0” / 0.75” | 1.0” / 0.75” | 1.0” / 0.75” | 1.0” / 0.75” | 1.25” / 0.75” |

| Cold W. Safety Devices – PRV, ERV, Chk Vlv | 1.0” (one piece) | 1.25” (multi-piece) | |||

| Exp. Relief Valve Setting – 3/6 bar kit (bar) | 6 / 8 | 6 / 8 | 6 / 8 | 6 / 8 | 6 / 8 |

| 2-port Mot. Valve (Indirect & Solar Only) | 28mm | 28mm | 28mm | 28mm | 1.25” |

| 2-port Mot. Valve Conn. (Ind & Sol Only) | Compression nut and olive | Pipe union conn. nut and tail piece | |||

| Expansion Vessel Size – 3/6 bar kit (ltr) | 24 / 35 | 35 / 50 | 50 / 80 | 80 / 100 | 100 / 150 |

| Tundish | 1.25” | 1.25” | 1.25” | 1.25” | 1.5” |

| ErP Energy Efficiency Class | C | C | C | C | C |

| Standing Loss (W) | 92 | 102 | 115 | 121 | 124 |

| Performance | 300 | 400 | 500 | 800 | 1000 |

| Inspection Flange | Optional | Optional | Optional | Optional | Optional |

| Heat Up Time ΔT 50°C (min)* | 23 | 26 | 30 | 48 | 62 |

| Hot Water Capacity (ltr) | 283 | 379 | 485 | 747 | 1079 |

| 1º Re-Heat time (70% draw off) 60L/min | 17 | 20 | 27 | 31 | 39 |

| 2º Re-Heat time (70% draw off) 30L/min | 24 | 28 | 37 | 48 | 57 |

| 3º Re-Heat time (70% draw off) 15L/min | 36 | 41 | 54 | 78 | 88 |

| Weight Empty (kg) | 82 | 87 | 104 | 220 | 230 |

| Weight Full (kg) | 365 | 466 | 589 | 967 | 1309 |

| Prim. Coil Surf. Area (m2) | 1.54 | 1.97 | 1.97 | 2.86 | 2.86 |

| Prim. Coil Rating @ 60L/min (kW) | 49 | 57 | 57 | 73 | 73 |

| Prim. Coil Rating @ 30L/min (kW) | 35.6 | 42 | 42 | 50 | 50 |

| Prim. Coil Rating @ 15L/min (kW) | 23 | 29 | 29 | 31 | 31 |

| Prim. Coil Press. Drop @ 15L/min (mbar) | 21 | 29 | 29 | 18 | 18 |

| Prim. Coil Press. Drop @ 30L/min (mbar) | 32 | 38 | 38 | 75 | 75 |

| Prim. Coil Press. Drop @ 60L/min (mbar) | 290 | 310 | 310 | 430 | 430 |

| Cont. Output @ 60ºC ΔT 50°C (L/hr) | 685 | 765 | 765 | 829 | 829 |

| Prim. Coil – Max Operating Press. (bar) | 6 | 6 | 6 | 6 | 6 |

Videos

Downloads

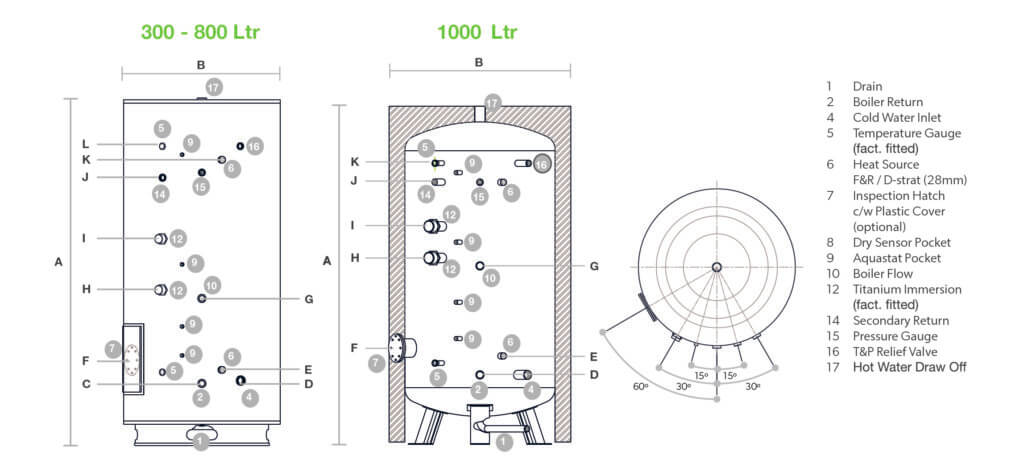

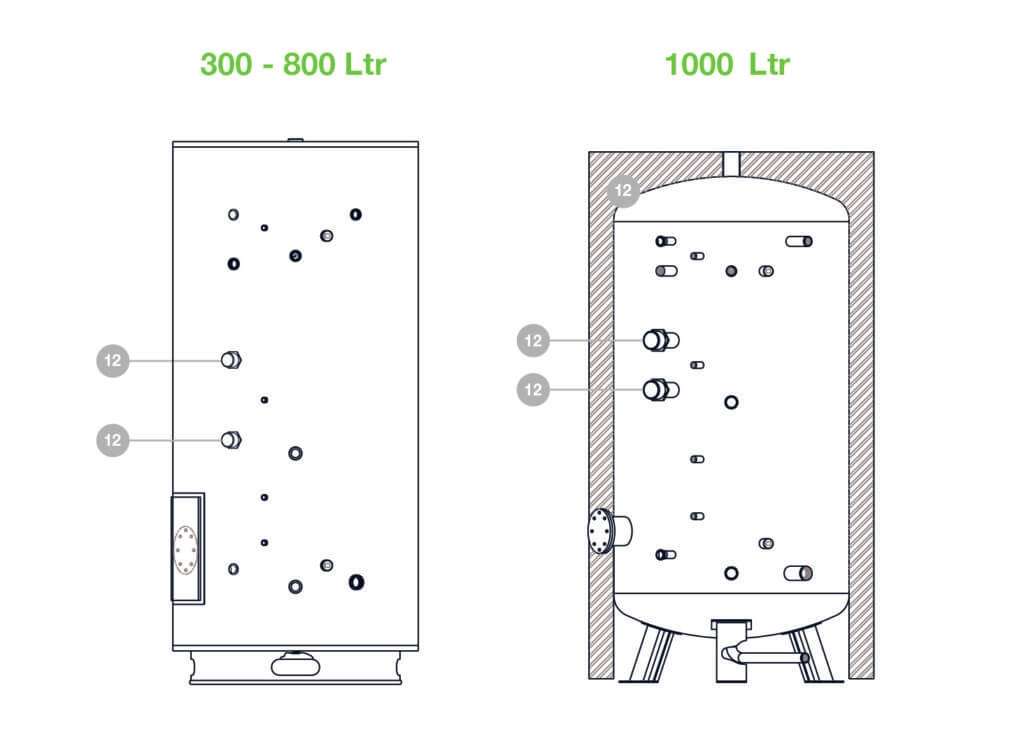

DIMS

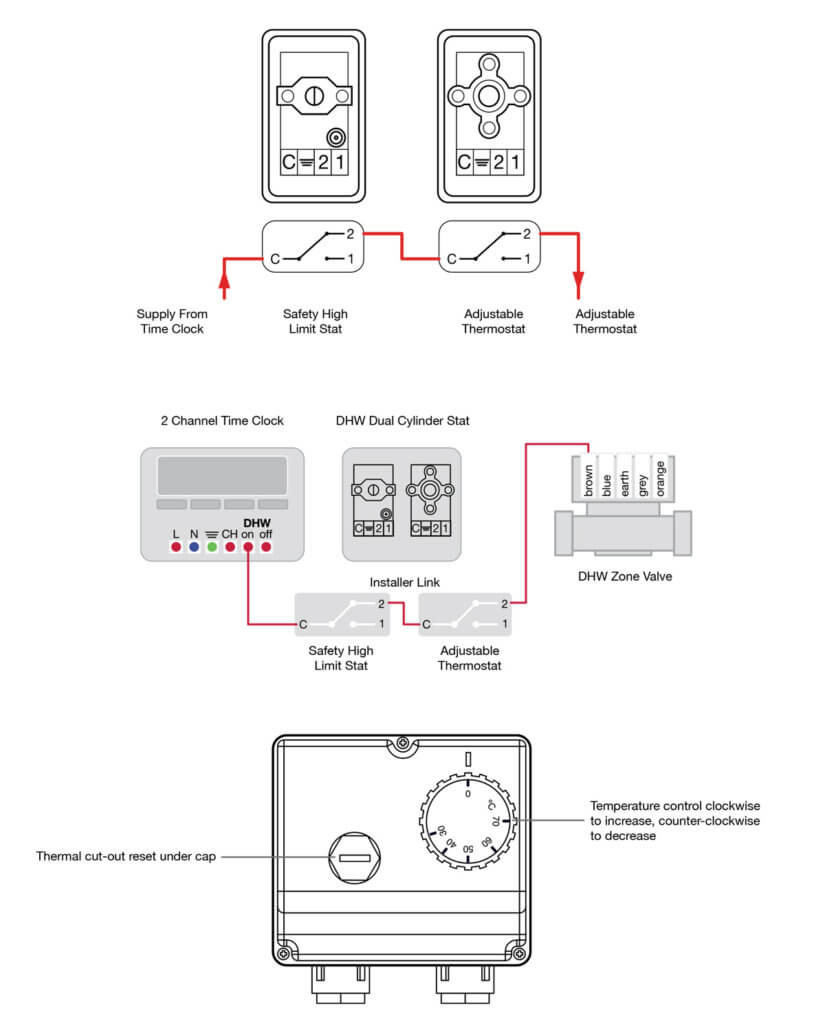

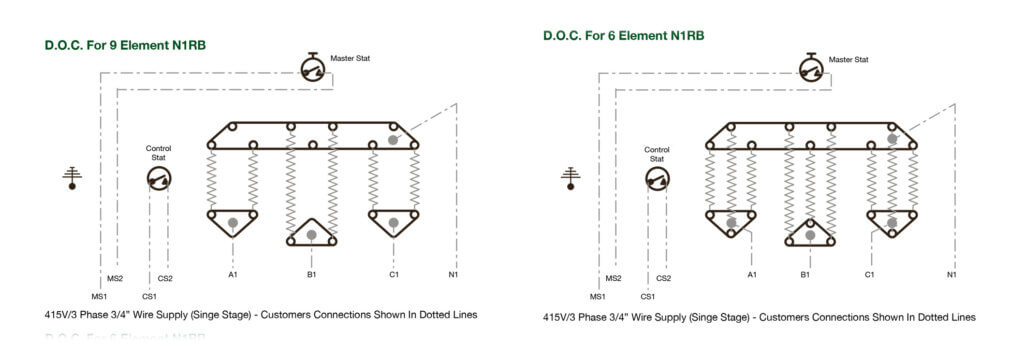

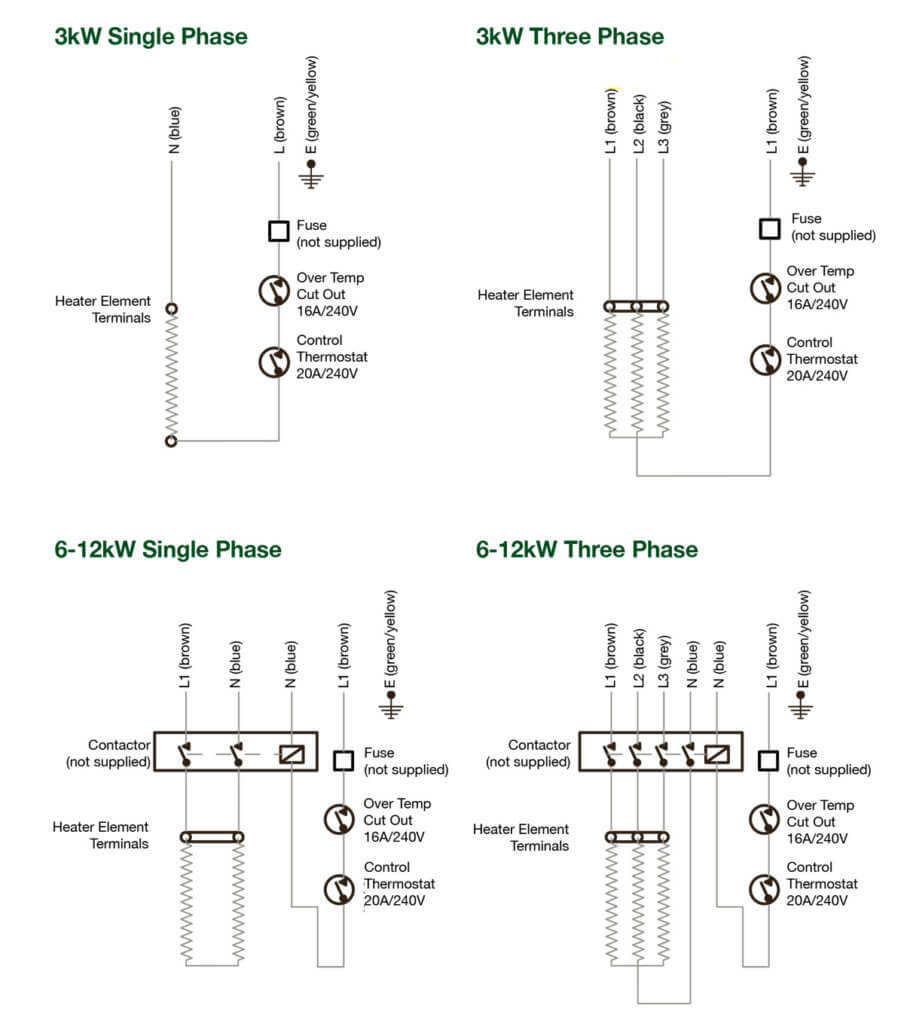

Electrical

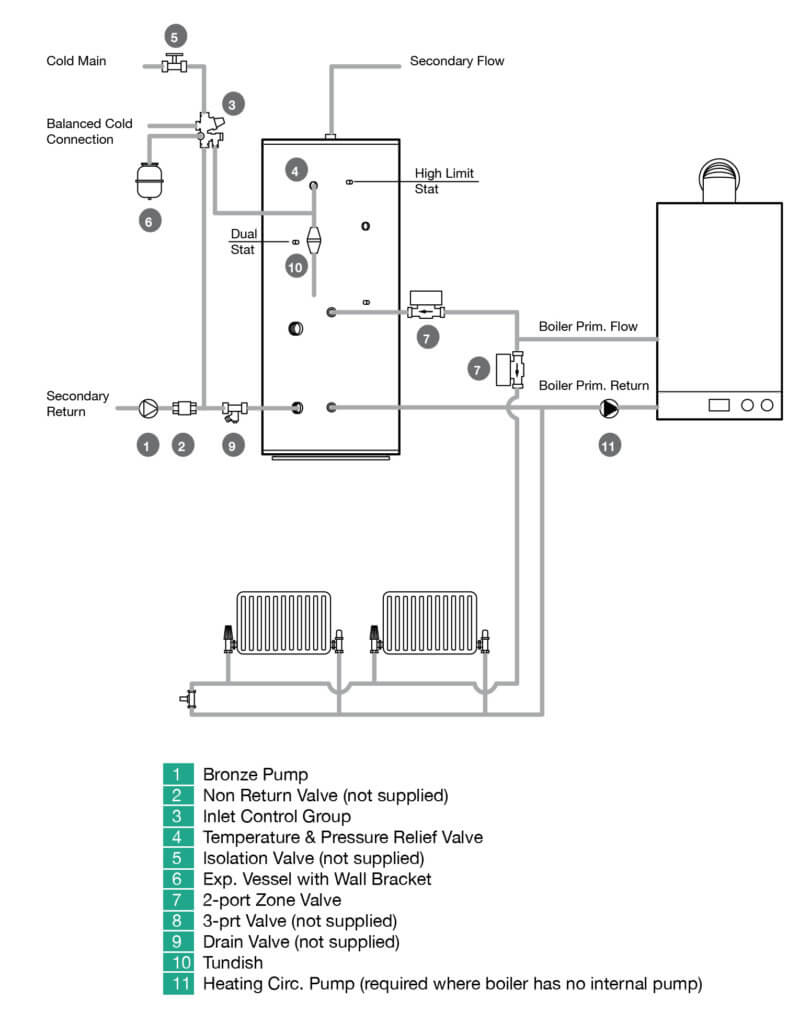

Mechanical

Spare Parts